Top 10 Benefits of Using Rubber Transmission Belts in Industrial Equipment

Table of Contents

1. Introduction

2. Improved Power Transmission

3. Enhanced Durability

4. Cost-Effectiveness

5. Reduced Maintenance

6. Noise Reduction

7. Increased Efficiency

8. Versatility

9. Environmental Friendliness

10. Smooth Operation

11. FAQs

12. Conclusion

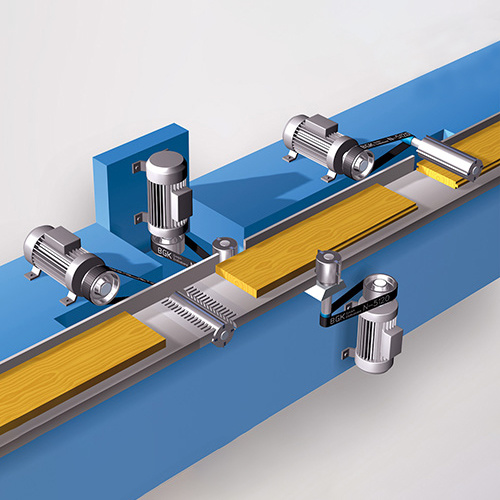

Rubber transmission belts play a crucial role in industrial equipment, facilitating the transfer of power and enabling smooth operation. These belts are widely used in different sectors such as manufacturing, mining, agriculture, and automotive industries. In this article, we will explore the top 10 benefits of using rubber transmission belts in industrial equipment.

One of the significant advantages of rubber transmission belts is their ability to efficiently transfer power from the motor to various components of the industrial equipment. These belts are designed to handle high levels of torque, ensuring a reliable and consistent power transfer. With their excellent grip and traction, rubber transmission belts can effectively transmit power even in challenging operating conditions.

Rubber transmission belts are known for their exceptional durability and longevity. They are constructed using high-quality rubber materials that are resistant to wear, tear, and abrasion. This durability ensures that the belts can withstand heavy loads, high speeds, and harsh environments without experiencing premature failure or damage. By using rubber transmission belts, industrial equipment can operate smoothly and reliably for extended periods, minimizing downtime and maintenance costs.

Opting for rubber transmission belts can be a cost-effective choice for industrial equipment owners. These belts are relatively affordable compared to alternative options, such as metal or plastic belts. Additionally, their long lifespan and resistance to wear result in fewer replacements and lower maintenance expenses. By investing in rubber transmission belts, businesses can save on operational costs while maintaining high-performance levels.

Industrial equipment often requires regular maintenance to ensure optimal performance. Rubber transmission belts contribute to reducing maintenance needs due to their durability and reliability. These belts are resistant to stretching, shrinking, and slipping, minimizing the need for frequent adjustments or replacements. Consequently, businesses can save time and resources that would otherwise be spent on ongoing maintenance tasks, leading to increased productivity.

Noise pollution can be a significant concern in industrial settings. Rubber transmission belts are designed to operate quietly, reducing noise levels and creating a more comfortable working environment. This noise reduction not only enhances the overall employee experience but also meets regulatory requirements. By utilizing rubber transmission belts, businesses can promote a quieter and safer workplace.

Rubber transmission belts offer high levels of efficiency in power transmission. With their excellent grip and minimal slippage, these belts ensure maximum power transfer from the motor to the driven components. This improved efficiency leads to enhanced overall equipment performance, reduced energy consumption, and optimized productivity. By utilizing rubber transmission belts, businesses can achieve higher output while minimizing energy costs.

Rubber transmission belts are available in a wide range of sizes, configurations, and designs, making them highly versatile for various industrial applications. Whether it is conveying materials, driving machinery, or operating heavy equipment, rubber transmission belts can be customized to meet specific requirements. This versatility allows businesses to choose the most suitable belt for their equipment, ensuring optimal performance and reliability.

With increasing emphasis on sustainability and environmental responsibility, rubber transmission belts offer a greener alternative to other types of belts. Rubber is a recyclable material, and many manufacturers produce belts using eco-friendly processes. By using rubber transmission belts, businesses can contribute to reducing their carbon footprint and align with environmentally conscious practices.

Industrial equipment relies on smooth and uninterrupted operation for efficient productivity. Rubber transmission belts provide a smooth power transmission, minimizing vibrations and shocks. This smooth operation not only prolongs the lifespan of the equipment but also reduces the risk of damage to delicate components. By incorporating rubber transmission belts, businesses can ensure a reliable and uninterrupted operation, leading to enhanced output.

Yes, rubber transmission belts are designed to handle heavy loads and are widely used in heavy-duty applications across various industries.

Rubber transmission belts are engineered to withstand a wide range of temperatures, from extreme cold to high heat, making them suitable for diverse operating environments.

The lifespan of rubber transmission belts can vary depending on several factors, such as usage, maintenance, and operating conditions. However, with proper care, these belts can last for several years.

Yes, rubber transmission belts have excellent resistance to moisture and can operate reliably in wet or humid conditions.

Rubber transmission belts are designed for easy installation and can be fitted onto equipment with minimal effort and time.

Rubber transmission belts offer a plethora of benefits for industrial equipment. From improved power transmission and enhanced durability to cost-effectiveness and reduced maintenance, these belts play a crucial role in optimizing productivity and performance. With their versatility and environmental friendliness, rubber transmission belts have become an indispensable component in various industries. Embrace the advantages of rubber transmission belts and elevate the efficiency of your industrial equipment to new heights.

1. Introduction

2. Improved Power Transmission

3. Enhanced Durability

4. Cost-Effectiveness

5. Reduced Maintenance

6. Noise Reduction

7. Increased Efficiency

8. Versatility

9. Environmental Friendliness

10. Smooth Operation

11. FAQs

12. Conclusion

1. Introduction

Rubber transmission belts play a crucial role in industrial equipment, facilitating the transfer of power and enabling smooth operation. These belts are widely used in different sectors such as manufacturing, mining, agriculture, and automotive industries. In this article, we will explore the top 10 benefits of using rubber transmission belts in industrial equipment.

2. Improved Power Transmission

One of the significant advantages of rubber transmission belts is their ability to efficiently transfer power from the motor to various components of the industrial equipment. These belts are designed to handle high levels of torque, ensuring a reliable and consistent power transfer. With their excellent grip and traction, rubber transmission belts can effectively transmit power even in challenging operating conditions.

3. Enhanced Durability

Rubber transmission belts are known for their exceptional durability and longevity. They are constructed using high-quality rubber materials that are resistant to wear, tear, and abrasion. This durability ensures that the belts can withstand heavy loads, high speeds, and harsh environments without experiencing premature failure or damage. By using rubber transmission belts, industrial equipment can operate smoothly and reliably for extended periods, minimizing downtime and maintenance costs.

4. Cost-Effectiveness

Opting for rubber transmission belts can be a cost-effective choice for industrial equipment owners. These belts are relatively affordable compared to alternative options, such as metal or plastic belts. Additionally, their long lifespan and resistance to wear result in fewer replacements and lower maintenance expenses. By investing in rubber transmission belts, businesses can save on operational costs while maintaining high-performance levels.

5. Reduced Maintenance

Industrial equipment often requires regular maintenance to ensure optimal performance. Rubber transmission belts contribute to reducing maintenance needs due to their durability and reliability. These belts are resistant to stretching, shrinking, and slipping, minimizing the need for frequent adjustments or replacements. Consequently, businesses can save time and resources that would otherwise be spent on ongoing maintenance tasks, leading to increased productivity.

6. Noise Reduction

Noise pollution can be a significant concern in industrial settings. Rubber transmission belts are designed to operate quietly, reducing noise levels and creating a more comfortable working environment. This noise reduction not only enhances the overall employee experience but also meets regulatory requirements. By utilizing rubber transmission belts, businesses can promote a quieter and safer workplace.

7. Increased Efficiency

Rubber transmission belts offer high levels of efficiency in power transmission. With their excellent grip and minimal slippage, these belts ensure maximum power transfer from the motor to the driven components. This improved efficiency leads to enhanced overall equipment performance, reduced energy consumption, and optimized productivity. By utilizing rubber transmission belts, businesses can achieve higher output while minimizing energy costs.

8. Versatility

Rubber transmission belts are available in a wide range of sizes, configurations, and designs, making them highly versatile for various industrial applications. Whether it is conveying materials, driving machinery, or operating heavy equipment, rubber transmission belts can be customized to meet specific requirements. This versatility allows businesses to choose the most suitable belt for their equipment, ensuring optimal performance and reliability.

9. Environmental Friendliness

With increasing emphasis on sustainability and environmental responsibility, rubber transmission belts offer a greener alternative to other types of belts. Rubber is a recyclable material, and many manufacturers produce belts using eco-friendly processes. By using rubber transmission belts, businesses can contribute to reducing their carbon footprint and align with environmentally conscious practices.

10. Smooth Operation

Industrial equipment relies on smooth and uninterrupted operation for efficient productivity. Rubber transmission belts provide a smooth power transmission, minimizing vibrations and shocks. This smooth operation not only prolongs the lifespan of the equipment but also reduces the risk of damage to delicate components. By incorporating rubber transmission belts, businesses can ensure a reliable and uninterrupted operation, leading to enhanced output.

11. FAQs

Q1: Are rubber transmission belts suitable for heavy-duty applications?

Yes, rubber transmission belts are designed to handle heavy loads and are widely used in heavy-duty applications across various industries.

Q2: Can rubber transmission belts withstand extreme temperatures?

Rubber transmission belts are engineered to withstand a wide range of temperatures, from extreme cold to high heat, making them suitable for diverse operating environments.

Q3: What is the average lifespan of rubber transmission belts?

The lifespan of rubber transmission belts can vary depending on several factors, such as usage, maintenance, and operating conditions. However, with proper care, these belts can last for several years.

Q4: Can rubber transmission belts be used in wet environments?

Yes, rubber transmission belts have excellent resistance to moisture and can operate reliably in wet or humid conditions.

Q5: Are rubber transmission belts easy to install?

Rubber transmission belts are designed for easy installation and can be fitted onto equipment with minimal effort and time.

12. Conclusion

Rubber transmission belts offer a plethora of benefits for industrial equipment. From improved power transmission and enhanced durability to cost-effectiveness and reduced maintenance, these belts play a crucial role in optimizing productivity and performance. With their versatility and environmental friendliness, rubber transmission belts have become an indispensable component in various industries. Embrace the advantages of rubber transmission belts and elevate the efficiency of your industrial equipment to new heights.

Related News