All You Need to Know About Rubber Transmission Belts in Industrial Machinery

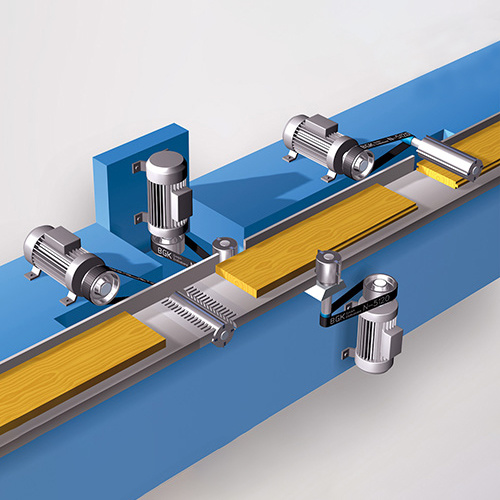

Rubber transmission belts are an essential component in industrial machinery, serving as a crucial part of the power transmission system. These belts are commonly used in various industries, including automotive, agriculture, and manufacturing, to transfer power from one rotating shaft to another.

One of the key advantages of rubber transmission belts is their flexibility and adaptability to different operating conditions. They are designed to withstand high temperatures, heavy loads, and harsh environments, making them ideal for a wide range of applications.

When it comes to installing and maintaining rubber transmission belts, there are a few key tips to keep in mind. Firstly, it is important to ensure that the belt is properly aligned and tensioned to prevent slipping and premature wear. Regular inspection of the belt for signs of damage, such as cracks or fraying, is also essential to prevent unexpected downtime and costly repairs.

Additionally, proper lubrication of the belt and pulleys can help extend the lifespan of the rubber transmission belt and improve its overall performance. Using the correct type of lubricant recommended by the manufacturer is crucial to avoid damaging the belt material.

In conclusion, rubber transmission belts play a vital role in industrial machinery, providing reliable power transmission and ensuring smooth operation. By understanding the functions and maintenance requirements of these belts, businesses in the industrial equipment and components industry can optimize their machinery's performance and longevity.

Related News

TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD

0086(0595)83112333

0086(0595)83112333

© Copyright 2024. TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD.