The Role of Flat Belts in Industrial Automation

**Introduction**

In the realm of industrial automation, flat belts are essential components that help streamline and optimize manufacturing processes. These versatile belts play a crucial role in various industries, from automotive to food and beverage, by providing a reliable method of transferring power and motion. In this article, we will explore the importance of flat belts in industrial automation and how they contribute to increased efficiency and productivity in the manufacturing sector.

**What are Flat Belts?**

Flat belts are continuous loops of material that are used to transmit power between two rotating shafts. They are typically made of rubber, leather, or synthetic materials and can be flat or V-shaped. Flat belts are known for their flexibility, durability, and ability to handle high speeds and heavy loads, making them ideal for a wide range of industrial applications.

**Types of Flat Belts**

There are several types of flat belts available in the market, each designed for specific applications. Some common types include:

- **Rubber Belts**: Rubber belts are highly flexible and resistant to abrasion, making them suitable for conveying materials in industrial settings.

- **Timing Belts**: Timing belts have teeth on the inner surface, allowing for precise motion control in machinery.

- **V-Belts**: V-belts have a V-shaped cross-section, providing better traction and efficiency in power transmission.

- **Polyurethane Belts**: Polyurethane belts offer excellent resistance to oils, chemicals, and abrasion, making them ideal for harsh environments.

**Benefits of Flat Belts in Industrial Automation**

Flat belts play a crucial role in industrial automation by providing several key benefits, including:

- **Efficient Power Transmission**: Flat belts offer smooth and reliable power transmission, ensuring consistent operation of machinery and equipment.

- **Low Maintenance**: Flat belts require minimal maintenance compared to other types of power transmission systems, reducing downtime and maintenance costs.

- **Cost-Effectiveness**: Flat belts are cost-effective solutions for power transmission, offering a high level of performance at a reasonable price.

- **Versatility**: Flat belts can be easily customized to fit specific applications, making them suitable for a wide range of industrial processes.

**Applications of Flat Belts in Industrial Automation**

Flat belts are widely used in various industrial automation applications, including:

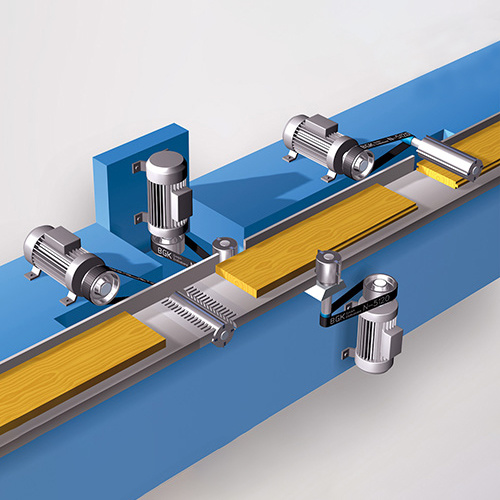

- **Conveyors**: Flat belts are commonly used in conveyor systems to transport materials and products along production lines.

- **Packaging Machinery**: Flat belts play a crucial role in packaging machinery by moving products through the packaging process efficiently.

- **Automotive Assembly**: Flat belts are used in automotive assembly lines to transfer components and parts between different stages of production.

- **Food Processing**: Flat belts are essential in food processing equipment for conveying, sorting, and packaging food products.

**FAQs**

1. **Are flat belts suitable for heavy-duty applications?**

- Yes, flat belts are designed to handle heavy loads and high speeds, making them ideal for heavy-duty industrial applications.

2. **Can flat belts be used in wet or oily environments?**

- Yes, some types of flat belts, such as polyurethane belts, are resistant to oils and chemicals, making them suitable for wet or oily environments.

3. **How often should flat belts be replaced?**

- Flat belts should be inspected regularly for wear and tear and replaced if signs of damage are present to prevent downtime and maintenance issues.

4. **What factors should be considered when selecting flat belts for an application?**

- When selecting flat belts, factors such as load capacity, speed, environment, and operational requirements should be taken into account to ensure optimal performance.

5. **Can flat belts be customized for specific applications?**

- Yes, flat belts can be customized in terms of material, size, and design to meet the specific requirements of an application.

**Conclusion**

Flat belts play a crucial role in industrial automation by providing efficient and reliable power transmission in a wide range of applications. With their versatility, durability, and cost-effectiveness, flat belts continue to be essential components in the manufacturing sector, contributing to increased efficiency and productivity. By understanding the importance of flat belts in industrial automation, companies can optimize their production processes and stay competitive in today's rapidly evolving industrial landscape.

Related News