Everything You Need to Know About Rubber Transmission Belts

Rubber transmission belts play a crucial role in the field of industrial equipment and components, specifically in the category of industrial belts. These belts, commonly known as rubber V-belts, are an integral part of industrial machinery and are used for power transmission.

1. What are rubber transmission belts?

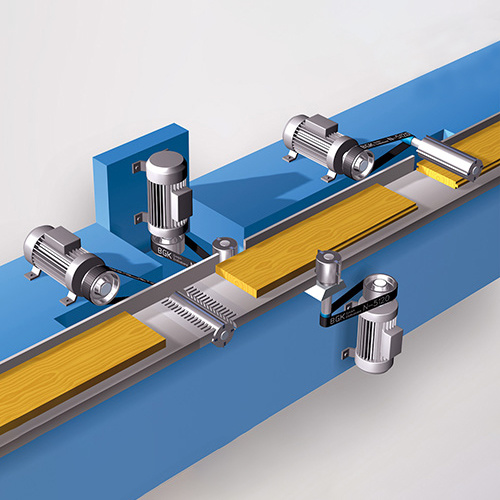

Rubber transmission belts are flexible, looped belts made of rubber materials. They are designed to transmit power between two shafts, enabling the movement of various industrial components. These belts are commonly used in machinery such as conveyor systems, mills, and manufacturing equipment.

2. How do rubber transmission belts work?

Rubber transmission belts work based on the principle of frictional force. As the belt comes into contact with pulleys or sheaves on the shafts, friction is created, allowing the transfer of rotational motion and power. The gripping action between the belt and the pulley ensures efficient power transmission.

3. What are the key features of rubber transmission belts?

Rubber transmission belts possess several features that make them suitable for industrial applications. They are highly flexible, resistant to wear and tear, and can withstand varying temperatures and environmental conditions. Additionally, they have excellent grip and traction properties, ensuring smooth power transmission.

4. What are the applications of rubber transmission belts?

Rubber transmission belts find usage in a wide range of industries. They are commonly employed in manufacturing plants, automotive production lines, agricultural machinery, mining equipment, and even in home appliances like washing machines and vacuum cleaners. These belts are essential for the smooth functioning of conveyor systems, power transmission systems, and other machinery.

5. What are the benefits of using rubber transmission belts?

Rubber transmission belts offer numerous advantages in industrial settings. They provide efficient power transmission, reducing energy loss and increasing overall productivity. The flexibility and durability of rubber belts ensure a longer service life, minimizing downtime and maintenance costs. Moreover, rubber belts offer noiseless operation, reducing the overall noise levels in the workplace.

In conclusion, rubber transmission belts are vital components in the industrial equipment and components sector. Their ability to transmit power efficiently, durability, and flexibility make them indispensable in various industries. Whether in conveyor systems or manufacturing equipment, rubber transmission belts play a significant role in keeping industrial machinery running smoothly.

1. What are rubber transmission belts?

Rubber transmission belts are flexible, looped belts made of rubber materials. They are designed to transmit power between two shafts, enabling the movement of various industrial components. These belts are commonly used in machinery such as conveyor systems, mills, and manufacturing equipment.

2. How do rubber transmission belts work?

Rubber transmission belts work based on the principle of frictional force. As the belt comes into contact with pulleys or sheaves on the shafts, friction is created, allowing the transfer of rotational motion and power. The gripping action between the belt and the pulley ensures efficient power transmission.

3. What are the key features of rubber transmission belts?

Rubber transmission belts possess several features that make them suitable for industrial applications. They are highly flexible, resistant to wear and tear, and can withstand varying temperatures and environmental conditions. Additionally, they have excellent grip and traction properties, ensuring smooth power transmission.

4. What are the applications of rubber transmission belts?

Rubber transmission belts find usage in a wide range of industries. They are commonly employed in manufacturing plants, automotive production lines, agricultural machinery, mining equipment, and even in home appliances like washing machines and vacuum cleaners. These belts are essential for the smooth functioning of conveyor systems, power transmission systems, and other machinery.

5. What are the benefits of using rubber transmission belts?

Rubber transmission belts offer numerous advantages in industrial settings. They provide efficient power transmission, reducing energy loss and increasing overall productivity. The flexibility and durability of rubber belts ensure a longer service life, minimizing downtime and maintenance costs. Moreover, rubber belts offer noiseless operation, reducing the overall noise levels in the workplace.

In conclusion, rubber transmission belts are vital components in the industrial equipment and components sector. Their ability to transmit power efficiently, durability, and flexibility make them indispensable in various industries. Whether in conveyor systems or manufacturing equipment, rubber transmission belts play a significant role in keeping industrial machinery running smoothly.

Related News

TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD

0086(0595)83112333

0086(0595)83112333

© Copyright 2024. TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD.

Business License