Precautions for Rubber Coated Conveyor Belts

⒈ Avoid the idler being covered by the material, causing the rotation to be ineffective, to prevent the leakage of the material from being stuck between the roller and the belt, pay attention to the lubrication of the moving part of the conveyor belt, but do not contaminate the conveyor belt;

⒉ Prevent conveyor belt load from starting;

3. If the conveyor belt deviates, measures should be taken to correct it in time;

⒋ When the conveyor belt is found to be damaged locally, use Kester 90T high-curing rubber repair paste or Futhorn rubber repair material to repair it in time to avoid expansion;

⒌ Prevent the conveyor belt from being blocked by the frame, pillars or block materials, and prevent it from being broken and torn.

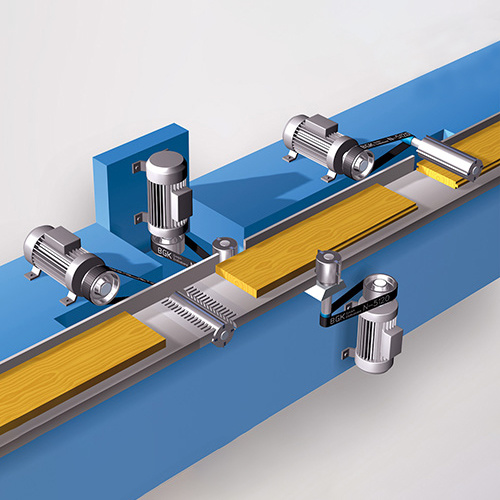

Conveyor belt is the main component of belt conveyor, mainly used for large-scale continuous transportation of coal, mining, metallurgy, chemical industry, construction and transportation, etc. The transported materials are divided into blocks, powder, paste and pieces items, etc. From the perspective of microscopic composition, the conveyor belt is mainly composed of three parts: skeleton material, covering layer and primer material, of which the covering layer is the key part that determines its performance and use.

Preceding Page:

Related News

TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD

0086(0595)83112333

0086(0595)83112333

© Copyright 2024. TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD.