All You Need to Know About Flat PVC Belts in Industrial Equipment

Flat PVC belts are essential components in the realm of industrial equipment and play a crucial role in power transmission. These belts are known for their versatility, durability, and efficiency in various applications. Here is all you need to know about flat PVC belts in industrial equipment:

1. Key Features:

- Flat PVC belts are made of polyvinyl chloride (PVC) material, which provides excellent resistance to abrasion, oil, and chemicals.

- These belts have a smooth surface, ensuring minimal friction and efficient power transmission.

- They are known for their flexibility, making them suitable for a wide range of industrial applications.

- Flat PVC belts come in various widths, lengths, and thicknesses to meet different industrial requirements.

2. Benefits:

- Flat PVC belts offer high tensile strength and excellent load-carrying capacity, making them ideal for heavy-duty applications.

- They are cost-effective and require minimal maintenance, resulting in reduced downtime and operational costs.

- The smooth surface of flat PVC belts reduces noise generation and vibration, ensuring a quieter and smoother operation.

- These belts are easy to install and replace, enhancing the overall efficiency and productivity of industrial equipment.

3. Applications:

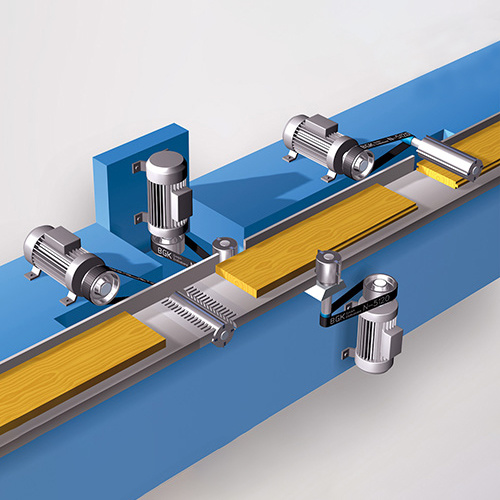

- Flat PVC belts are commonly used in conveyor systems for transporting materials in manufacturing plants, warehouses, and distribution centers.

- They are suitable for applications requiring high grip, such as incline or decline conveyors and food processing industries.

- Flat PVC belts are also used in packaging equipment, automotive assembly lines, and agricultural machinery.

In conclusion, flat PVC belts are indispensable components in industrial equipment, offering a wide range of benefits and applications. Their durability, efficiency, and versatility make them a preferred choice for power transmission in various industries. Whether it's for conveyor systems, packaging equipment, or automotive assembly lines, flat PVC belts play a vital role in ensuring smooth and efficient operations.

1. Key Features:

- Flat PVC belts are made of polyvinyl chloride (PVC) material, which provides excellent resistance to abrasion, oil, and chemicals.

- These belts have a smooth surface, ensuring minimal friction and efficient power transmission.

- They are known for their flexibility, making them suitable for a wide range of industrial applications.

- Flat PVC belts come in various widths, lengths, and thicknesses to meet different industrial requirements.

2. Benefits:

- Flat PVC belts offer high tensile strength and excellent load-carrying capacity, making them ideal for heavy-duty applications.

- They are cost-effective and require minimal maintenance, resulting in reduced downtime and operational costs.

- The smooth surface of flat PVC belts reduces noise generation and vibration, ensuring a quieter and smoother operation.

- These belts are easy to install and replace, enhancing the overall efficiency and productivity of industrial equipment.

3. Applications:

- Flat PVC belts are commonly used in conveyor systems for transporting materials in manufacturing plants, warehouses, and distribution centers.

- They are suitable for applications requiring high grip, such as incline or decline conveyors and food processing industries.

- Flat PVC belts are also used in packaging equipment, automotive assembly lines, and agricultural machinery.

In conclusion, flat PVC belts are indispensable components in industrial equipment, offering a wide range of benefits and applications. Their durability, efficiency, and versatility make them a preferred choice for power transmission in various industries. Whether it's for conveyor systems, packaging equipment, or automotive assembly lines, flat PVC belts play a vital role in ensuring smooth and efficient operations.

Preceding Page:

Related News

TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD

0086(0595)83112333

0086(0595)83112333

© Copyright 2024. TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD.

Business License