The Advantages of Using Rubber Polyamide Flat Belts in Industrial Equipment

Table of Contents:

1. Introduction

2. Understanding Rubber Polyamide Flat Belts

3. Enhanced Durability and Longevity

4. Optimal Performance and Efficiency

5. Reduced Maintenance and Downtime

6. Versatility and Adaptability

7. Cost-Effective Solution

8. Environmental Friendliness

9. Frequently Asked Questions (FAQs)

10. Conclusion

In today's fast-paced industrial landscape, efficiency and reliability are paramount for businesses to thrive. One crucial aspect of industrial equipment is the use of belts that facilitate the smooth operation of various machinery. Among the many options available, rubber polyamide flat belts have emerged as a preferred choice for numerous industries. This article explores the advantages of using rubber polyamide flat belts in industrial equipment and how they can help your business excel.

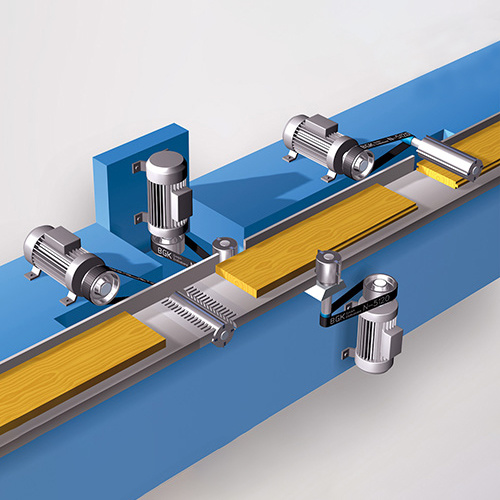

Rubber polyamide flat belts are a type of power transmission belt made from a blend of rubber and polyamide materials. These belts are specifically designed to transmit power efficiently between the driving and driven pulleys in industrial machinery. They are known for their flexibility, strength, and ability to withstand heavy loads and high-speed applications.

One of the primary advantages of rubber polyamide flat belts is their exceptional durability and longevity. The combination of rubber and polyamide materials creates a belt that can withstand harsh operating conditions, including extreme temperatures, moisture, and chemicals. This durability ensures minimal wear and tear, reducing the need for frequent replacements and resulting in significant cost savings.

Rubber polyamide flat belts offer excellent traction, allowing them to transfer power efficiently and effectively. Their high coefficient of friction ensures optimal performance, even in demanding applications. These belts also exhibit minimal stretching, maintaining constant speed and accuracy, thereby enhancing overall equipment efficiency. With reduced slippage and improved power transmission, industrial equipment can operate at peak performance levels.

By choosing rubber polyamide flat belts for your industrial equipment, you can significantly reduce maintenance requirements and minimize downtime. These belts are resistant to abrasion and require less lubrication compared to other belt materials. As a result, you can avoid frequent belt adjustments, replacements, and unscheduled downtime, saving both time and money.

Rubber polyamide flat belts are highly versatile and adaptable, making them suitable for a wide range of industrial applications. Whether it's conveyor systems, packaging machinery, or manufacturing equipment, these belts can easily accommodate various configurations. Their flexibility allows for seamless integration into existing systems, ensuring smooth operation and compatibility with different pulley sizes and designs.

Investing in rubber polyamide flat belts offers significant cost advantages in the long run. Their durability and longevity minimize the need for frequent replacements, reducing maintenance costs. Furthermore, their superior performance and efficiency contribute to energy savings and increased productivity. By choosing these belts, businesses can achieve a higher return on investment while ensuring reliable and uninterrupted operation.

In today's environmentally conscious world, the use of sustainable materials is crucial. Rubber polyamide flat belts are an eco-friendly choice due to their composition and manufacturing process. The combination of rubber and polyamide materials ensures a reduced environmental impact compared to traditional belt options. By opting for these belts, businesses can contribute to a greener future while meeting sustainability goals.

Yes, rubber polyamide flat belts are engineered to withstand high-speed applications. Their design and material composition ensure optimal performance and reliability even in demanding industrial settings.

Absolutely. These belts are renowned for their strength and load-bearing capabilities. They are designed to support heavy loads without compromising performance or longevity.

Rubber polyamide flat belts have minimal maintenance requirements. They are resistant to abrasion and require less lubrication compared to other belt materials, resulting in reduced maintenance costs and efforts.

Yes, rubber polyamide flat belts can be easily customized to suit specific industrial equipment requirements. Manufacturers offer a variety of sizes, widths, and configurations to cater to diverse application needs.

Absolutely. The durability and longevity of rubber polyamide flat belts translate into cost savings over time. Their minimal need for replacements and reduced maintenance contribute to overall cost-effectiveness.

Rubber polyamide flat belts offer numerous advantages for industrial equipment applications. Their durability, optimal performance, reduced maintenance, versatility, cost-effectiveness, and environmental friendliness make them a preferred choice for various industries. By incorporating these belts into your machinery, you can enhance efficiency, minimize downtime, and achieve long-term cost savings. Invest in rubber polyamide flat belts today and witness the transformative impact they bring to your industrial operations.

1. Introduction

2. Understanding Rubber Polyamide Flat Belts

3. Enhanced Durability and Longevity

4. Optimal Performance and Efficiency

5. Reduced Maintenance and Downtime

6. Versatility and Adaptability

7. Cost-Effective Solution

8. Environmental Friendliness

9. Frequently Asked Questions (FAQs)

10. Conclusion

1. Introduction

In today's fast-paced industrial landscape, efficiency and reliability are paramount for businesses to thrive. One crucial aspect of industrial equipment is the use of belts that facilitate the smooth operation of various machinery. Among the many options available, rubber polyamide flat belts have emerged as a preferred choice for numerous industries. This article explores the advantages of using rubber polyamide flat belts in industrial equipment and how they can help your business excel.

2. Understanding Rubber Polyamide Flat Belts

Rubber polyamide flat belts are a type of power transmission belt made from a blend of rubber and polyamide materials. These belts are specifically designed to transmit power efficiently between the driving and driven pulleys in industrial machinery. They are known for their flexibility, strength, and ability to withstand heavy loads and high-speed applications.

3. Enhanced Durability and Longevity

One of the primary advantages of rubber polyamide flat belts is their exceptional durability and longevity. The combination of rubber and polyamide materials creates a belt that can withstand harsh operating conditions, including extreme temperatures, moisture, and chemicals. This durability ensures minimal wear and tear, reducing the need for frequent replacements and resulting in significant cost savings.

4. Optimal Performance and Efficiency

Rubber polyamide flat belts offer excellent traction, allowing them to transfer power efficiently and effectively. Their high coefficient of friction ensures optimal performance, even in demanding applications. These belts also exhibit minimal stretching, maintaining constant speed and accuracy, thereby enhancing overall equipment efficiency. With reduced slippage and improved power transmission, industrial equipment can operate at peak performance levels.

5. Reduced Maintenance and Downtime

By choosing rubber polyamide flat belts for your industrial equipment, you can significantly reduce maintenance requirements and minimize downtime. These belts are resistant to abrasion and require less lubrication compared to other belt materials. As a result, you can avoid frequent belt adjustments, replacements, and unscheduled downtime, saving both time and money.

6. Versatility and Adaptability

Rubber polyamide flat belts are highly versatile and adaptable, making them suitable for a wide range of industrial applications. Whether it's conveyor systems, packaging machinery, or manufacturing equipment, these belts can easily accommodate various configurations. Their flexibility allows for seamless integration into existing systems, ensuring smooth operation and compatibility with different pulley sizes and designs.

7. Cost-Effective Solution

Investing in rubber polyamide flat belts offers significant cost advantages in the long run. Their durability and longevity minimize the need for frequent replacements, reducing maintenance costs. Furthermore, their superior performance and efficiency contribute to energy savings and increased productivity. By choosing these belts, businesses can achieve a higher return on investment while ensuring reliable and uninterrupted operation.

8. Environmental Friendliness

In today's environmentally conscious world, the use of sustainable materials is crucial. Rubber polyamide flat belts are an eco-friendly choice due to their composition and manufacturing process. The combination of rubber and polyamide materials ensures a reduced environmental impact compared to traditional belt options. By opting for these belts, businesses can contribute to a greener future while meeting sustainability goals.

9. Frequently Asked Questions (FAQs)

FAQ 1: Are rubber polyamide flat belts suitable for high-speed applications?

Yes, rubber polyamide flat belts are engineered to withstand high-speed applications. Their design and material composition ensure optimal performance and reliability even in demanding industrial settings.

FAQ 2: Can rubber polyamide flat belts handle heavy loads?

Absolutely. These belts are renowned for their strength and load-bearing capabilities. They are designed to support heavy loads without compromising performance or longevity.

FAQ 3: Do rubber polyamide flat belts require special maintenance?

Rubber polyamide flat belts have minimal maintenance requirements. They are resistant to abrasion and require less lubrication compared to other belt materials, resulting in reduced maintenance costs and efforts.

FAQ 4: Can rubber polyamide flat belts be customized for specific applications?

Yes, rubber polyamide flat belts can be easily customized to suit specific industrial equipment requirements. Manufacturers offer a variety of sizes, widths, and configurations to cater to diverse application needs.

FAQ 5: Are rubber polyamide flat belts cost-effective in the long run?

Absolutely. The durability and longevity of rubber polyamide flat belts translate into cost savings over time. Their minimal need for replacements and reduced maintenance contribute to overall cost-effectiveness.

10. Conclusion

Rubber polyamide flat belts offer numerous advantages for industrial equipment applications. Their durability, optimal performance, reduced maintenance, versatility, cost-effectiveness, and environmental friendliness make them a preferred choice for various industries. By incorporating these belts into your machinery, you can enhance efficiency, minimize downtime, and achieve long-term cost savings. Invest in rubber polyamide flat belts today and witness the transformative impact they bring to your industrial operations.

Related News