Maximize Efficiency with Industrial Rubber Synchronous Belts

Table of Contents:

1. Introduction: The Power of Industrial Rubber Synchronous Belts

2. Understanding the Mechanics of Industrial Rubber Synchronous Belts

3. Benefits of Industrial Rubber Synchronous Belts

4. Choosing the Right Industrial Rubber Synchronous Belt for Your Application

5. Common FAQs about Industrial Rubber Synchronous Belts

6. Conclusion

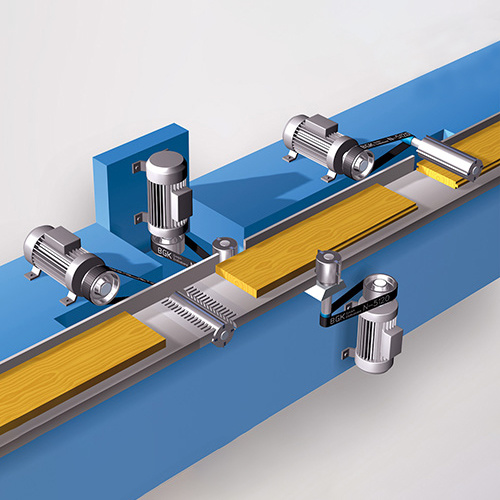

In today's fast-paced industrial landscape, maximizing efficiency is vital for any operation to thrive. One technology that has proven to be a game-changer in improving productivity and reducing downtime is industrial rubber synchronous belts. These belts, made from high-quality rubber materials and equipped with advanced toothed designs, offer a range of advantages that can greatly enhance the performance of various industrial systems.

Industrial rubber synchronous belts operate on the principle of synchronous power transmission. Unlike traditional V-belts, these belts feature toothed profiles, which enable precise engagement with the pulleys. This synchronized movement eliminates slippage and ensures efficient power transfer, even under high loads and speed variations.

The high-quality rubber material used in manufacturing these belts provides excellent flexibility, durability, and resistance to wear and tear. The toothed design offers enhanced grip and reduces the risk of belt slipping, resulting in a more reliable and efficient power transmission system.

3.1 Increased Efficiency:

By eliminating slippage and ensuring precise power transfer, industrial rubber synchronous belts significantly improve operational efficiency. This reduction in energy loss translates into increased productivity and cost savings for industrial applications.

3.2 Enhanced Durability:

The high-quality rubber material used in manufacturing these belts ensures exceptional durability, even in demanding industrial environments. These belts can withstand extreme temperatures, harsh chemicals, and heavy loads, making them ideal for various industrial applications.

3.3 Reduced Maintenance:

Industrial rubber synchronous belts require minimal maintenance compared to traditional belt options. With their advanced toothed design and durable rubber material, these belts offer extended service life and reduce the need for frequent replacements or adjustments.

3.4 Noise Reduction:

The toothed design of industrial rubber synchronous belts minimizes vibration and noise levels during operation. This benefit is particularly crucial in noise-sensitive environments, promoting a safer and more comfortable working environment.

3.5 Versatility:

Industrial rubber synchronous belts are available in a wide range of sizes, profiles, and configurations to suit different industrial applications. From automotive manufacturing to food processing, these belts can be customized to meet specific operational requirements.

Selecting the appropriate industrial rubber synchronous belt for your application is crucial to maximize efficiency and performance. Here are some factors to consider:

4.1 Load and Speed Requirements:

Evaluate the load and speed variations in your application to determine the required belt strength and tooth profile. Consider factors such as torque, horsepower, and pulley arrangements to ensure optimal power transmission.

4.2 Environmental Conditions:

Assess the environmental conditions in which the belt will operate. Consider temperature fluctuations, exposure to chemicals, and the presence of dust or moisture. Choose a belt that offers suitable resistance and durability to withstand these conditions.

4.3 Application Specifics:

Identify any unique requirements of your application, such as space constraints or noise reduction needs. Consult with belt manufacturers or experts to choose a belt that addresses these specifics.

Q1: Can industrial rubber synchronous belts replace other types of belts?

A1: Industrial rubber synchronous belts are a superior alternative to traditional V-belts in many applications. However, it is essential to evaluate the specific requirements of your application to determine if synchronous belts are the most suitable choice.

Q2: How often should industrial rubber synchronous belts be replaced?

A2: The service life of industrial rubber synchronous belts varies depending on factors such as operating conditions, load, and maintenance practices. Regular inspections and monitoring of belt condition can help determine when replacements are necessary.

Q3: Can industrial rubber synchronous belts handle high-speed applications?

A3: Yes, industrial rubber synchronous belts are designed to handle high-speed operations while maintaining efficient power transmission. It is crucial to select belts with suitable tooth profiles and materials for optimal performance.

Q4: Are industrial rubber synchronous belts suitable for food processing applications?

A4: Yes, industrial rubber synchronous belts can be customized to meet the stringent requirements of food processing applications. These belts are available in food-grade materials that comply with industry regulations.

Q5: Can industrial rubber synchronous belts improve energy efficiency?

A5: Absolutely! Industrial rubber synchronous belts minimize energy loss by eliminating slippage and ensuring precise power transmission. This improvement in energy efficiency can lead to substantial cost savings over time.

In conclusion, industrial rubber synchronous belts are a powerful tool for maximizing efficiency and productivity in various industrial applications. With their advanced toothed design, high-quality rubber material, and numerous benefits, these belts offer a reliable solution for efficient power transmission.

When selecting industrial rubber synchronous belts, consider factors such as load and speed requirements, environmental conditions, and application specifics to ensure optimal performance. By harnessing the power of these belts, you can enhance your operations, reduce downtime, and stay ahead in today's competitive industrial landscape.

1. Introduction: The Power of Industrial Rubber Synchronous Belts

2. Understanding the Mechanics of Industrial Rubber Synchronous Belts

3. Benefits of Industrial Rubber Synchronous Belts

4. Choosing the Right Industrial Rubber Synchronous Belt for Your Application

5. Common FAQs about Industrial Rubber Synchronous Belts

6. Conclusion

1. Introduction: The Power of Industrial Rubber Synchronous Belts

In today's fast-paced industrial landscape, maximizing efficiency is vital for any operation to thrive. One technology that has proven to be a game-changer in improving productivity and reducing downtime is industrial rubber synchronous belts. These belts, made from high-quality rubber materials and equipped with advanced toothed designs, offer a range of advantages that can greatly enhance the performance of various industrial systems.

2. Understanding the Mechanics of Industrial Rubber Synchronous Belts

Industrial rubber synchronous belts operate on the principle of synchronous power transmission. Unlike traditional V-belts, these belts feature toothed profiles, which enable precise engagement with the pulleys. This synchronized movement eliminates slippage and ensures efficient power transfer, even under high loads and speed variations.

The high-quality rubber material used in manufacturing these belts provides excellent flexibility, durability, and resistance to wear and tear. The toothed design offers enhanced grip and reduces the risk of belt slipping, resulting in a more reliable and efficient power transmission system.

3. Benefits of Industrial Rubber Synchronous Belts

3.1 Increased Efficiency:

By eliminating slippage and ensuring precise power transfer, industrial rubber synchronous belts significantly improve operational efficiency. This reduction in energy loss translates into increased productivity and cost savings for industrial applications.

3.2 Enhanced Durability:

The high-quality rubber material used in manufacturing these belts ensures exceptional durability, even in demanding industrial environments. These belts can withstand extreme temperatures, harsh chemicals, and heavy loads, making them ideal for various industrial applications.

3.3 Reduced Maintenance:

Industrial rubber synchronous belts require minimal maintenance compared to traditional belt options. With their advanced toothed design and durable rubber material, these belts offer extended service life and reduce the need for frequent replacements or adjustments.

3.4 Noise Reduction:

The toothed design of industrial rubber synchronous belts minimizes vibration and noise levels during operation. This benefit is particularly crucial in noise-sensitive environments, promoting a safer and more comfortable working environment.

3.5 Versatility:

Industrial rubber synchronous belts are available in a wide range of sizes, profiles, and configurations to suit different industrial applications. From automotive manufacturing to food processing, these belts can be customized to meet specific operational requirements.

4. Choosing the Right Industrial Rubber Synchronous Belt for Your Application

Selecting the appropriate industrial rubber synchronous belt for your application is crucial to maximize efficiency and performance. Here are some factors to consider:

4.1 Load and Speed Requirements:

Evaluate the load and speed variations in your application to determine the required belt strength and tooth profile. Consider factors such as torque, horsepower, and pulley arrangements to ensure optimal power transmission.

4.2 Environmental Conditions:

Assess the environmental conditions in which the belt will operate. Consider temperature fluctuations, exposure to chemicals, and the presence of dust or moisture. Choose a belt that offers suitable resistance and durability to withstand these conditions.

4.3 Application Specifics:

Identify any unique requirements of your application, such as space constraints or noise reduction needs. Consult with belt manufacturers or experts to choose a belt that addresses these specifics.

5. Common FAQs about Industrial Rubber Synchronous Belts

Q1: Can industrial rubber synchronous belts replace other types of belts?

A1: Industrial rubber synchronous belts are a superior alternative to traditional V-belts in many applications. However, it is essential to evaluate the specific requirements of your application to determine if synchronous belts are the most suitable choice.

Q2: How often should industrial rubber synchronous belts be replaced?

A2: The service life of industrial rubber synchronous belts varies depending on factors such as operating conditions, load, and maintenance practices. Regular inspections and monitoring of belt condition can help determine when replacements are necessary.

Q3: Can industrial rubber synchronous belts handle high-speed applications?

A3: Yes, industrial rubber synchronous belts are designed to handle high-speed operations while maintaining efficient power transmission. It is crucial to select belts with suitable tooth profiles and materials for optimal performance.

Q4: Are industrial rubber synchronous belts suitable for food processing applications?

A4: Yes, industrial rubber synchronous belts can be customized to meet the stringent requirements of food processing applications. These belts are available in food-grade materials that comply with industry regulations.

Q5: Can industrial rubber synchronous belts improve energy efficiency?

A5: Absolutely! Industrial rubber synchronous belts minimize energy loss by eliminating slippage and ensuring precise power transmission. This improvement in energy efficiency can lead to substantial cost savings over time.

6. Conclusion

In conclusion, industrial rubber synchronous belts are a powerful tool for maximizing efficiency and productivity in various industrial applications. With their advanced toothed design, high-quality rubber material, and numerous benefits, these belts offer a reliable solution for efficient power transmission.

When selecting industrial rubber synchronous belts, consider factors such as load and speed requirements, environmental conditions, and application specifics to ensure optimal performance. By harnessing the power of these belts, you can enhance your operations, reduce downtime, and stay ahead in today's competitive industrial landscape.

Related News