Choosing the Right Flat Transmission Belt for Your Industrial Machinery

Table of Contents:

1. Introduction: Understanding the Importance of Choosing the Right Flat Transmission Belt

2. Factors to Consider When Selecting a Flat Transmission Belt for Your Industrial Machinery

3. Types of Flat Transmission Belts for Different Industrial Applications

4. Assessing the Durability and Strength of Flat Transmission Belts

5. The Role of Material Composition in Flat Transmission Belts

6. Understanding Belt Tension and Load Capacity for Maximum Efficiency

7. Maintenance and Care Tips for Prolonged Belt Lifespan

8. Frequently Asked Questions (FAQs) about Flat Transmission Belts

9. Conclusion: Maximizing Performance with the Perfect Flat Transmission Belt

1. Introduction: Understanding the Importance of Choosing the Right Flat Transmission Belt

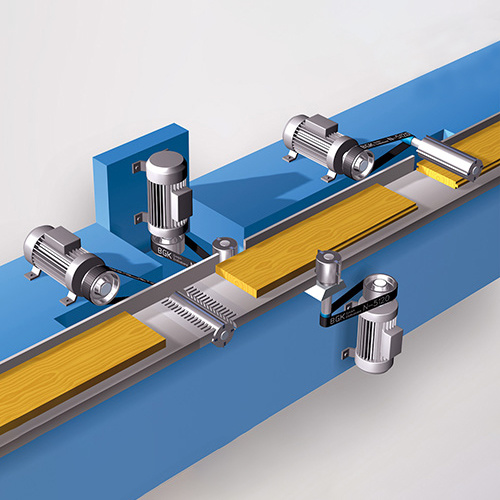

When it comes to industrial machinery, the performance and efficiency of the equipment rely heavily on the choice of transmission belt. A flat transmission belt is a key component that ensures smooth power transfer and movement within different industrial applications. However, selecting the right flat transmission belt can be a challenging task. In this article, we will guide you through the process of choosing the perfect flat transmission belt for your industrial machinery, helping you optimize performance and productivity.

2. Factors to Consider When Selecting a Flat Transmission Belt for Your Industrial Machinery

2.1 Load Requirements: Understanding the amount of load your machinery will bear is crucial when selecting a flat transmission belt. Consider the maximum load capacity and ensure the belt can handle the required weight without compromising performance.

2.2 Speed and Power Transmission: Different industrial applications demand varying speed and power requirements. Assess the necessary rotational speed and power transmission needed for your machinery, and choose a belt capable of meeting these requirements.

2.3 Environmental Conditions: Take into account the operating environment of your machinery. Factors such as temperature, humidity, dust, and chemicals can significantly impact the performance of a flat transmission belt. Ensure the chosen belt is resistant to these conditions for long-lasting performance.

2.4 Belt Width and Length: Proper sizing of the flat transmission belt is essential for optimal performance. Measure the belt dimensions accurately to ensure a perfect fit and prevent slippage or excessive tension.

3. Types of Flat Transmission Belts for Different Industrial Applications

3.1 Rubber Flat Transmission Belts: Known for their flexibility and high grip, rubber belts are suitable for applications requiring moderate power transmission. They are commonly used in industries such as agriculture, packaging, and textiles.

3.2 Nylon Flat Transmission Belts: Nylon belts offer excellent resistance to abrasion, making them ideal for heavy-duty applications. They are commonly used in industries like mining, construction, and steel manufacturing.

3.3 Polyurethane Flat Transmission Belts: With their high resistance to chemicals, oils, and extreme temperatures, polyurethane belts are perfect for industries requiring precise power transmission. They find application in industries like food processing, automotive, and electronics.

4. Assessing the Durability and Strength of Flat Transmission Belts

The durability and strength of a flat transmission belt are critical for prolonged operational lifespan. Consider factors such as the belt's tensile strength, flex fatigue resistance, and overall construction quality. Look for belts with reinforced layers, high-quality materials, and superior bonding to ensure enhanced durability and minimal downtime.

5. The Role of Material Composition in Flat Transmission Belts

The material composition of a flat transmission belt has a significant impact on its performance. Common materials used include rubber, nylon, polyester, and polyurethane. Each material offers specific advantages and disadvantages, so it's essential to choose one that suits your industrial application's requirements.

6. Understanding Belt Tension and Load Capacity for Maximum Efficiency

Proper belt tension is crucial for optimal performance and efficiency. Over-tensioning can lead to excessive wear and premature failure, while under-tensioning can result in slippage and reduced power transmission. Consult the manufacturer's guidelines or seek professional advice to ensure the correct tension and load capacity for your specific machinery.

7. Maintenance and Care Tips for Prolonged Belt Lifespan

To maximize the lifespan of your flat transmission belt, regular maintenance and care are essential. Clean the belt regularly to prevent the buildup of dirt and debris. Inspect for signs of wear, cracking, or damage, and replace the belt when necessary. Proper lubrication and belt alignment also contribute to prolonged belt lifespan and efficient machinery operation.

8. Frequently Asked Questions (FAQs) about Flat Transmission Belts

Q1: How often should I replace my flat transmission belt?

Q2: Can I use a standard belt for heavy-duty applications?

Q3: What are the signs of a worn-out flat transmission belt?

Q4: Are there any specific lubrication requirements for flat transmission belts?

Q5: Can I repair a damaged flat transmission belt, or is replacement necessary?

9. Conclusion: Maximizing Performance with the Perfect Flat Transmission Belt

Choosing the right flat transmission belt for your industrial machinery is crucial for optimal performance and efficiency. By considering factors such as load requirements, speed, environmental conditions, and material composition, you can select a belt that meets your specific needs. Regular maintenance and care will ensure a prolonged lifespan for your flat transmission belt, maximizing productivity and minimizing downtime. Selecting the perfect flat transmission belt will undoubtedly enhance the performance of your industrial machinery and help you stay ahead in the competitive market.

1. Introduction: Understanding the Importance of Choosing the Right Flat Transmission Belt

2. Factors to Consider When Selecting a Flat Transmission Belt for Your Industrial Machinery

3. Types of Flat Transmission Belts for Different Industrial Applications

4. Assessing the Durability and Strength of Flat Transmission Belts

5. The Role of Material Composition in Flat Transmission Belts

6. Understanding Belt Tension and Load Capacity for Maximum Efficiency

7. Maintenance and Care Tips for Prolonged Belt Lifespan

8. Frequently Asked Questions (FAQs) about Flat Transmission Belts

9. Conclusion: Maximizing Performance with the Perfect Flat Transmission Belt

1. Introduction: Understanding the Importance of Choosing the Right Flat Transmission Belt

When it comes to industrial machinery, the performance and efficiency of the equipment rely heavily on the choice of transmission belt. A flat transmission belt is a key component that ensures smooth power transfer and movement within different industrial applications. However, selecting the right flat transmission belt can be a challenging task. In this article, we will guide you through the process of choosing the perfect flat transmission belt for your industrial machinery, helping you optimize performance and productivity.

2. Factors to Consider When Selecting a Flat Transmission Belt for Your Industrial Machinery

2.1 Load Requirements: Understanding the amount of load your machinery will bear is crucial when selecting a flat transmission belt. Consider the maximum load capacity and ensure the belt can handle the required weight without compromising performance.

2.2 Speed and Power Transmission: Different industrial applications demand varying speed and power requirements. Assess the necessary rotational speed and power transmission needed for your machinery, and choose a belt capable of meeting these requirements.

2.3 Environmental Conditions: Take into account the operating environment of your machinery. Factors such as temperature, humidity, dust, and chemicals can significantly impact the performance of a flat transmission belt. Ensure the chosen belt is resistant to these conditions for long-lasting performance.

2.4 Belt Width and Length: Proper sizing of the flat transmission belt is essential for optimal performance. Measure the belt dimensions accurately to ensure a perfect fit and prevent slippage or excessive tension.

3. Types of Flat Transmission Belts for Different Industrial Applications

3.1 Rubber Flat Transmission Belts: Known for their flexibility and high grip, rubber belts are suitable for applications requiring moderate power transmission. They are commonly used in industries such as agriculture, packaging, and textiles.

3.2 Nylon Flat Transmission Belts: Nylon belts offer excellent resistance to abrasion, making them ideal for heavy-duty applications. They are commonly used in industries like mining, construction, and steel manufacturing.

3.3 Polyurethane Flat Transmission Belts: With their high resistance to chemicals, oils, and extreme temperatures, polyurethane belts are perfect for industries requiring precise power transmission. They find application in industries like food processing, automotive, and electronics.

4. Assessing the Durability and Strength of Flat Transmission Belts

The durability and strength of a flat transmission belt are critical for prolonged operational lifespan. Consider factors such as the belt's tensile strength, flex fatigue resistance, and overall construction quality. Look for belts with reinforced layers, high-quality materials, and superior bonding to ensure enhanced durability and minimal downtime.

5. The Role of Material Composition in Flat Transmission Belts

The material composition of a flat transmission belt has a significant impact on its performance. Common materials used include rubber, nylon, polyester, and polyurethane. Each material offers specific advantages and disadvantages, so it's essential to choose one that suits your industrial application's requirements.

6. Understanding Belt Tension and Load Capacity for Maximum Efficiency

Proper belt tension is crucial for optimal performance and efficiency. Over-tensioning can lead to excessive wear and premature failure, while under-tensioning can result in slippage and reduced power transmission. Consult the manufacturer's guidelines or seek professional advice to ensure the correct tension and load capacity for your specific machinery.

7. Maintenance and Care Tips for Prolonged Belt Lifespan

To maximize the lifespan of your flat transmission belt, regular maintenance and care are essential. Clean the belt regularly to prevent the buildup of dirt and debris. Inspect for signs of wear, cracking, or damage, and replace the belt when necessary. Proper lubrication and belt alignment also contribute to prolonged belt lifespan and efficient machinery operation.

8. Frequently Asked Questions (FAQs) about Flat Transmission Belts

Q1: How often should I replace my flat transmission belt?

Q2: Can I use a standard belt for heavy-duty applications?

Q3: What are the signs of a worn-out flat transmission belt?

Q4: Are there any specific lubrication requirements for flat transmission belts?

Q5: Can I repair a damaged flat transmission belt, or is replacement necessary?

9. Conclusion: Maximizing Performance with the Perfect Flat Transmission Belt

Choosing the right flat transmission belt for your industrial machinery is crucial for optimal performance and efficiency. By considering factors such as load requirements, speed, environmental conditions, and material composition, you can select a belt that meets your specific needs. Regular maintenance and care will ensure a prolonged lifespan for your flat transmission belt, maximizing productivity and minimizing downtime. Selecting the perfect flat transmission belt will undoubtedly enhance the performance of your industrial machinery and help you stay ahead in the competitive market.

Related News