All You Need to Know about Wrapped Banded V Belts in Industrial Power Transmission

Introduction:

In the realm of industrial equipment and components, wrapped banded V belts play a vital role in power transmission. This article delves into the intricacies of wrapped banded V belts, offering a comprehensive understanding of their significance, advantages, and usage in various industrial settings. Whether you're a professional in the field or simply seeking knowledge about these essential belts, read on to unlock valuable insights.

1. What are Wrapped Banded V Belts?

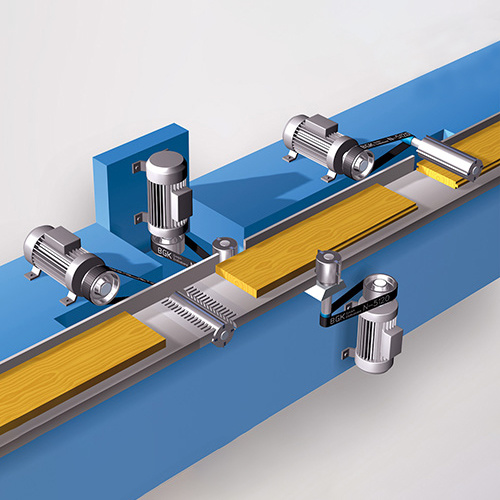

Wrapped banded V belts are specialized industrial belts designed to transmit power between the driving and driven components of machinery. They consist of multiple V-belts joined together by a continuous band, forming a single unit. The belts are made from a rubber or neoprene compound and reinforced with polyester cords for enhanced strength and durability.

2. Features and Benefits:

- Enhanced Power Transmission: Wrapped banded V belts provide efficient power transmission due to the increased contact surface area between the belt and pulleys. This results in improved torque transfer and reduced slip.

- Increased Load Capacity: The continuous band in wrapped banded V belts distributes the load evenly across the belts, enabling them to handle higher loads. They are particularly suitable for heavy-duty applications.

- Reduced Vibrations and Noise: The design of wrapped banded V belts minimizes vibrations and noise, ensuring smoother and quieter operation of industrial equipment. This contributes to a more comfortable working environment.

- Heat and Oil Resistance: The rubber or neoprene compound used in wrapped banded V belts offers excellent resistance to heat and oil, prolonging their lifespan even in demanding industrial environments.

3. Applications:

Wrapped banded V belts find applications in various industrial sectors, including:

- HVAC Systems: They are used in air handling units, fans, and blowers to transmit power efficiently and reliably.

- Agricultural Machinery: Wrapped banded V belts drive essential components in agricultural equipment such as combines, tractors, and harvesters.

- Industrial Machinery: From conveyor systems to industrial compressors, wrapped banded V belts ensure smooth power transmission in a wide range of machinery.

- Manufacturing Equipment: Many manufacturing processes rely on wrapped banded V belts for efficient power transmission, including packaging machines, assembly lines, and more.

In conclusion, wrapped banded V belts are an indispensable component in industrial power transmission systems. Their unique design and advantages, including enhanced power transmission, increased load capacity, reduced vibrations, and heat/oil resistance, make them a preferred choice in various industries. By understanding their features and applications, you can optimize the performance and reliability of your industrial equipment.

In the realm of industrial equipment and components, wrapped banded V belts play a vital role in power transmission. This article delves into the intricacies of wrapped banded V belts, offering a comprehensive understanding of their significance, advantages, and usage in various industrial settings. Whether you're a professional in the field or simply seeking knowledge about these essential belts, read on to unlock valuable insights.

1. What are Wrapped Banded V Belts?

Wrapped banded V belts are specialized industrial belts designed to transmit power between the driving and driven components of machinery. They consist of multiple V-belts joined together by a continuous band, forming a single unit. The belts are made from a rubber or neoprene compound and reinforced with polyester cords for enhanced strength and durability.

2. Features and Benefits:

- Enhanced Power Transmission: Wrapped banded V belts provide efficient power transmission due to the increased contact surface area between the belt and pulleys. This results in improved torque transfer and reduced slip.

- Increased Load Capacity: The continuous band in wrapped banded V belts distributes the load evenly across the belts, enabling them to handle higher loads. They are particularly suitable for heavy-duty applications.

- Reduced Vibrations and Noise: The design of wrapped banded V belts minimizes vibrations and noise, ensuring smoother and quieter operation of industrial equipment. This contributes to a more comfortable working environment.

- Heat and Oil Resistance: The rubber or neoprene compound used in wrapped banded V belts offers excellent resistance to heat and oil, prolonging their lifespan even in demanding industrial environments.

3. Applications:

Wrapped banded V belts find applications in various industrial sectors, including:

- HVAC Systems: They are used in air handling units, fans, and blowers to transmit power efficiently and reliably.

- Agricultural Machinery: Wrapped banded V belts drive essential components in agricultural equipment such as combines, tractors, and harvesters.

- Industrial Machinery: From conveyor systems to industrial compressors, wrapped banded V belts ensure smooth power transmission in a wide range of machinery.

- Manufacturing Equipment: Many manufacturing processes rely on wrapped banded V belts for efficient power transmission, including packaging machines, assembly lines, and more.

In conclusion, wrapped banded V belts are an indispensable component in industrial power transmission systems. Their unique design and advantages, including enhanced power transmission, increased load capacity, reduced vibrations, and heat/oil resistance, make them a preferred choice in various industries. By understanding their features and applications, you can optimize the performance and reliability of your industrial equipment.

Related News

TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD

0086(0595)83112333

0086(0595)83112333

© Copyright 2024. TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD.

Business License