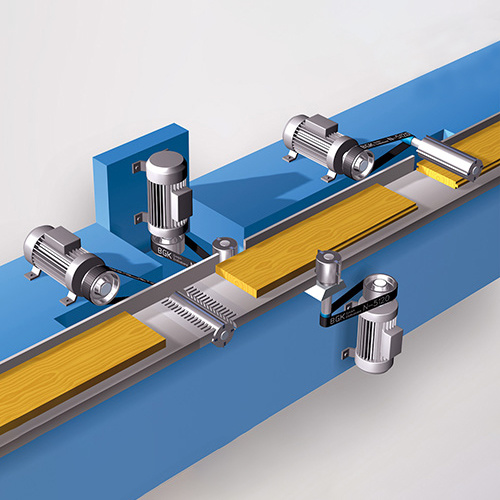

TIGER Conveyor Belt with Guide Strips & Cleats Solutions

Have you ever run into these tricky conveying problems: material deviation, slipping during inclined conveying, or inaccurate positioning?

01 Core Functions: What Exactly Do Guide Strips, Cleats & Sidewalls do?

Guide Strips (Profiles):

Their key role is precision positioning + deviation prevention. By attaching raised guide strips onto the conveyor belt, materials are guided to move along a fixed path, eliminating offset issues effectively. Ideal for assembly lines where neat arrangement is required, such as electronic components and packaged food lines, ensuring smooth running of subsequent processes.

Cleats:

Their core function is enhanced lifting conveying + material separation. During inclined or vertical conveying, cleats can "hold" materials in place to prevent slipping; meanwhile, they can separate materials from different batches. For instance, in the lifting and conveying of grain and ore, cleats are the key to enabling high-drop conveying.

Sidewalls:

They mainly solve the problem of material side leakage. When used together with cleats, they allow for steep-angle (even nearly vertical) conveying. Perfect for powdery and granular materials (e.g., chemical fertilizers, cement, grains), avoiding material waste from scattering.

02 Technical Highlights: Core Advantages of TIGER’s Processing Solutions

TIGER (Fujian) Industrial Belt Co., Ltd. leverages advanced technology and customization capabilities to meet the needs of various complex application scenarios:

- Advanced Processing Technology

High-precision equipment is adopted to ensure perfect fitting between guide strips/cleats/sidewalls and the conveyor belt. This guarantees stable operation after installation, reducing abrasion and noise significantly.

- Full Range of Specifications Available

We offer products ranging from micro guide strips (K6/KN6) to large-sized cleats (T100/TD100), and from thin to thick sidewalls. Our products are compatible with minimum roller diameters from 20mm to 200mm, suiting small assembly lines to large-scale lifting equipment.

- Flexible Material Options

Two material options are available: PVC and PU.

- PVC: Cost-effective, suitable for general-purpose scenarios.

- PU: Oil-resistant and low-temperature resistant, ideal for high-end industries like food and pharmaceuticals.

- Customization Capabilities

- We provide tailored solutions for special scenarios (e.g., high-temperature, high-abrasion, or low-temperature environments).

03 Application Cases: Industries Already Benefiting from Our Products

Guide strips and cleats are widely used across various industries—see if yours is on the list:

- Food Industry: Food-grade PVC/PU guide strips (K6/KN6) and cleats (T20) are used for conveying biscuits and candies. They prevent deviation and slipping during inclined conveying, complying with strict hygiene standards.

- Electronics Industry: Guide strips (K10/KN10) ensure precise positioning of PCB boards, avoiding component damage and improving sorting efficiency by over 30%.

- Logistics & Warehousing: Cleats (T50/TN50) separate different packages, and sidewalls with a height of over 50mm prevent slipping on slopes, reducing package mixing and damage.

- Pharmaceutical Industry: Food-grade guide strips and cleats meet the hygiene requirements for pharmaceutical conveying, ensuring the safety and reliability of drug packaging.

04 TIGER’s Technical Strengths: Customized Solutions

Equipped with advanced equipment and special processing technology, TIGER (Fujian) Industrial Belt Co., Ltd. provides you with exclusive conveying solutions:

- Advanced Equipment: High-precision processing equipment ensures a seamless fit between guide strips/cleats and the conveyor belt, eliminating gaps and material jamming.

- Special Processing: Customized specifications (e.g., non-standard dimensions and materials) are available to meet on-site special needs (e.g., high/low-temperature environments).

- Professional Services: We offer one-on-one recommendations of optimal specifications based on your specific conveying conditions (inclined angle, material weight, positioning accuracy), ensuring a highly targeted solution.

Related News