Discussion on Transmission Belt

The transmission belt is an essential component in various industries. It finds wide applications in manufacturing, where it is used to transfer power and motion between different parts of machinery. In the automotive industry, transmission belts play a crucial role in the operation of engines, ensuring smooth power transmission to different components.

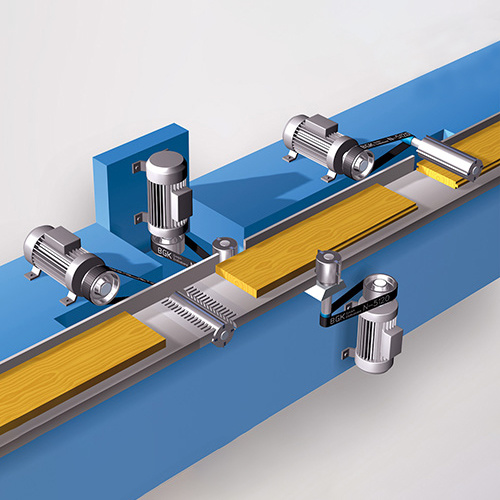

The application scenarios of transmission belts are very wide. It can be seen in the power and related light and medium-sized transportation of various industries. In the textile industry, equipment such as wire grabbing machines and double twisting machines cannot do without the efficient transmission of transmission belts; in the printing industry, offset printing machines, multi-drilling machines, etc., transmission belts ensure the smooth progress of the printing process; automatic box gluing machines in the packaging industry, woodworking machines, ventilators and crushers in the woodworking industry, transmission belts are key components for their stable operation. It can be said that transmission belts silently support the daily operations of many industries.

Transmission belts have many characteristics. As one of them, nylon sheet base belts show the advantages of light weight, high strength, small elongation, good oil resistance and wear resistance, soft belt body, and energy saving. This makes it easy to cope with various working environments and requirements in practical applications, which can not only ensure efficient and stable transmission, but also reduce energy consumption. Polyester transmission belts are famous for their high reliability, long service life and outstanding damping characteristics. It is particularly suitable for high-speed machines, and performs well in dealing with complex situations such as the opposite bending of the small wheel diameter, providing reliable power transmission guarantee for high-speed equipment.

The role of the transmission belt cannot be underestimated. It is like a "power bridge" for industrial equipment, accurately and efficiently transmitting the energy of the power source to each working part. Through the connection and transmission of the transmission belt, different machines and equipment can work in coordination to achieve the continuity and automation of the production process. Its existence not only improves production efficiency and reduces labor costs, but also ensures the consistency and stability of product quality.

In the context of the continuous development of science and technology today, the transmission belt is also constantly innovating and evolving. New materials and technologies are constantly applied to the manufacture of transmission belts, making their performance more excellent and adaptable to more complex and harsh working conditions. At the same time, with the continuous improvement of production efficiency and quality requirements in various industries, the transmission belt is also constantly improving its quality and function to better meet market demand.

In short, as an important industrial component, the transmission belt occupies an indispensable position in the modern industrial system with its wide range of application scenarios, unique characteristics and key roles. With the advancement of technology and the expansion of application fields, the transmission belt will continue to contribute to the development of various industries and become one of the important forces to promote industrial progress.

Preceding Page:

Related News

TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD

0086(0595)83112333

0086(0595)83112333

© Copyright 2024. TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD.