The Versatile Power of Nylon Transmission Belts in Manufacturing Facility

In the ever-evolving landscape of industrial machinery and automation, the choice of materials for critical components can significantly impact efficiency, durability, and overall performance. One such material that has stood the test of time is nylon. Widely recognized for its strength, resilience, and low-maintenance properties, nylon transmission belts have become a staple in various industries. This article delves into the applications, benefits, and unique selling points of nylon transmission belts, illustrating why they are indispensable in manufacturing facility.

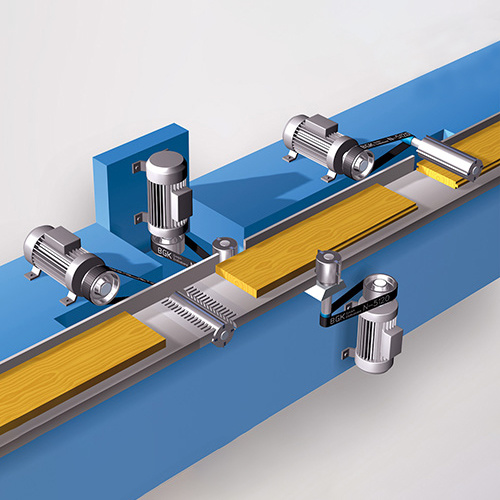

Nylon transmission belts are engineered to withstand the rigors of industrial environments, making them ideal for use in a wide range of applications. From conveyor systems and material handling equipment to agricultural machinery and automotive applications, these belts are designed to provide reliable power transmission solutions. Their versatility stems from their ability to maintain high levels of performance under varying load conditions, ensuring consistent operation across diverse industrial settings.

One of the primary advantages of nylon transmission belts is their exceptional strength-to-weight ratio. This characteristic allows for the efficient transfer of power while minimizing energy consumption. In comparison to other materials like metal chains or rubber belts, nylon offers a lightweight yet robust solution that reduces wear and tear on bearings and shafts. This not only extends the lifespan of the entire system but also contributes to cost savings by reducing maintenance requirements.

Another significant benefit of nylon transmission belts lies in their resistance to environmental factors such as moisture, oils, and chemicals. Unlike natural fibers, which can degrade when exposed to these elements, nylon remains unaffected, maintaining its integrity and functionality over time. This makes it an ideal choice for applications in harsh environments where exposure to contaminants is inevitable. Additionally, nylon's non-abrasive nature ensures that it does not cause damage to pulleys or sprockets during operation, further enhancing its longevity.

The ease of installation and replacement is another compelling reason for choosing nylon transmission belts. With their flexible nature, these belts can be easily fitted onto existing equipment without the need for specialized tools or skills. Moreover, if a belt were to fail due to excessive wear or damage, replacing it is straightforward and cost-effective. This feature minimizes downtime and maximizes productivity, which is crucial in fast-paced industrial settings.

In terms of value proposition, nylon transmission belts offer a combination of durability, efficiency, and cost-effectiveness that is hard to match. By reducing operational costs through lower maintenance needs and extending the lifespan of associated machinery, these belts provide a substantial return on investment. Furthermore, their adaptability to different working conditions means that businesses can standardize their operations around a single type of belt, simplifying inventory management and reducing training requirements for staff.

To summarize, nylon transmission belts have proven themselves to be a vital component in manufacturing facility due to their superior strength, resistance to environmental factors, ease of installation and replacement, and overall value proposition. As industries continue to evolve towards increased automation and efficiency, the role of nylon transmission belts will undoubtedly grow, solidifying their place as a cornerstone of industrial innovation.

Related News

TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD

0086(0595)83112333

0086(0595)83112333

© Copyright 2024. TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD.