The Importance of Power Rubber Flat Transmission Belts in Modern Automation Industry

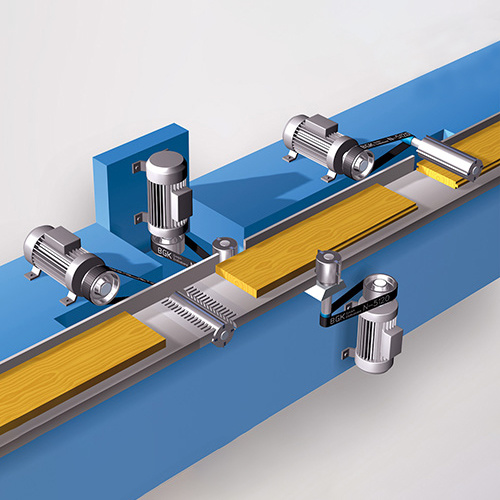

In the realm of modern automation industry, the efficiency and reliability of machinery are paramount. One crucial component that ensures seamless operation across various industrial applications is the power rubber flat transmission belt. These belts play a pivotal role in transmitting mechanical power from one shaft to another, enabling the smooth functioning of conveyor systems, motors, and other mechanical assemblies. This article delves into the significance of power rubber flat transmission belts, exploring their applications, benefits, and why they have become indispensable in industrial settings.

Understanding Power Rubber Flat Transmission Belts

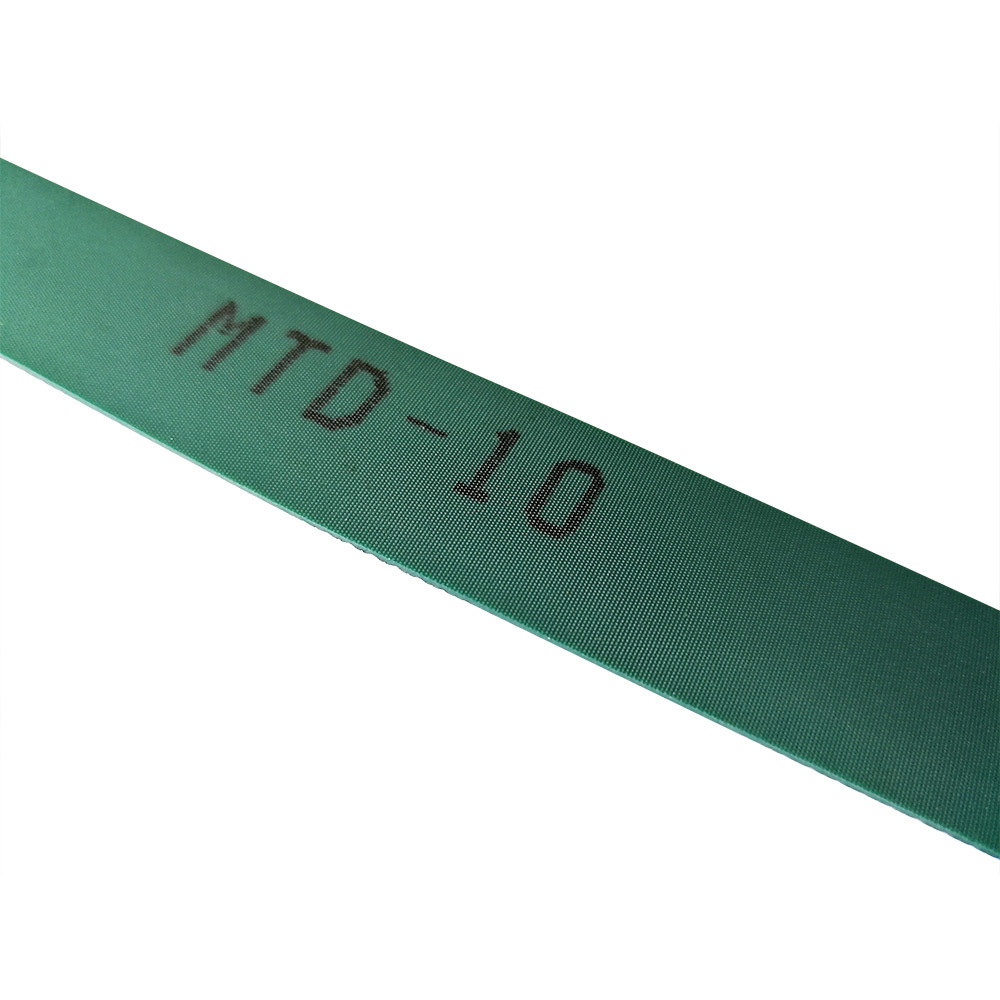

A power rubber flat transmission belt is a flexible, rubber-based belt used in mechanical drives to transfer power between shafts. Unlike traditional V-belts, which rely on wedged contact with pulley grooves, flat transmission belts utilize frictional contact between the belt's surface and the pulley. This design allows for more precise control over the drive system, reducing slippage and enhancing power transmission efficiency.

Key Features of Power Rubber Flat Transmission Belts

1.Durability: Made from high-quality rubber compounds, these belts are designed to withstand harsh industrial environments, resisting wear and tear, and ensuring long-term performance.

2.Flexibility: The flexibility of power rubber flat transmission belts enables them to conform to different pulley sizes and shapes, making them versatile for various applications.

3.Noise Reduction: Compared to metal chains or gears, flat transmission belts operate quietly, contributing to a quieter work environment.

4.Maintenance-Free: Unlike some mechanical components that require regular lubrication or adjustment, flat transmission belts need minimal maintenance, reducing downtime and operational costs.

Power rubber flat transmission belts are crucial in modern automation industry for their ability to efficiently transfer power between shafts with minimal energy loss. Their durability, flexibility, and low maintenance requirements make them ideal for a wide range of applications, from conveyor systems to motor drives and HVAC equipment. These belts enhance machinery performance, reduce operational costs, and ensure reliable and continuous operation in industrial settings.

Related News

TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD

0086(0595)83112333

0086(0595)83112333

© Copyright 2024. TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD.