Processing method of antibacterial PU conveyor belt for dough machine

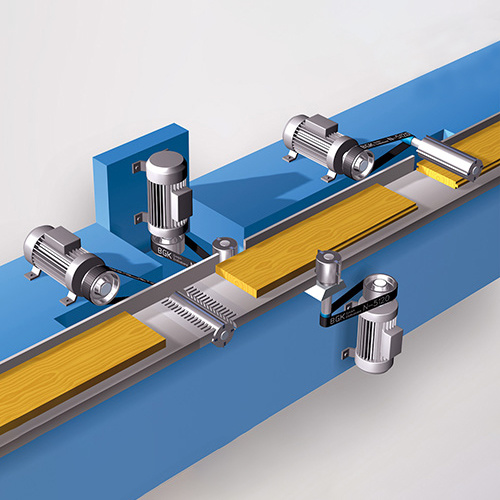

In the food industry, conveyor belts have relatively high requirements for food transportation, and those that meet the food grade are suitable for conveying food. Therefore, many factories need customized processing. Let me introduce to you what are the suitable processing methods for the antibacterial PU conveyor belt for leather machines?

1. Conveyor belt customization and guide strips Add one or more belts on the conveyor belt to guide the conveyor belt to run, position the conveyor belt for the food industry, and prevent the conveyor belt from swinging, deviation, guiding, and fixing. Prevent swinging.

2. Customized and foamed conveyor belt A layer of foam is added to the conveyor belt to prevent vibration.

3. Custom punching. For the perforation of conveyor belts, conveyor belt work generally requires perforation when suction is required. The size and distance of the holes can be adjusted according to the requirements of the suction and food industry. Requirements for conveying products on conveyor belts

4. Customize and block. For the conveyor belt, the stopper is also determined according to the requirements of the conveyor belt. Whether it is necessary to separate the products conveyed in the food industry, or whether the conveyor belt needs to support the product upward with stops because it is going uphill.

5. Conveyor belt custom plus skirt The conveyor belt plus skirt is to increase the shape of the skirt on both sides of the conveyor belt used in the food industry to prevent the material from flowing out.

Preceding Page:

Related News

TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD

0086(0595)83112333

0086(0595)83112333

© Copyright 2024. TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD.