Choosing the Right Width for Industrial Flat Transmission Belts

Industrial flat transmission belts are essential components in various industrial machinery and equipment, providing the necessary power transmission for smooth operation. One crucial factor to consider when choosing these belts is their width, as it directly impacts their efficiency and performance. In this article, we will discuss the importance of selecting the right width for industrial flat transmission belts and provide useful tips to help you make the best decision for your specific needs.

## Understanding Industrial Flat Transmission Belts

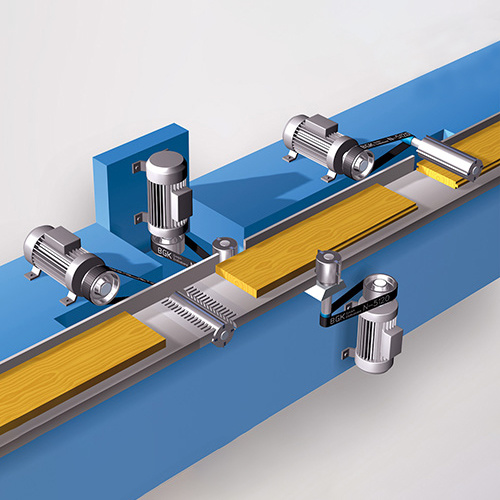

Before delving into the details of choosing the right width for industrial flat transmission belts, it is essential to understand their role and function in industrial applications. These belts are commonly used for power transmission in machinery such as conveyor systems, packaging equipment, and manufacturing processes. They are designed to transfer power from one pulley to another efficiently, ensuring smooth and consistent operation.

### Factors to Consider When Selecting Belt Width

When it comes to choosing the right width for industrial flat transmission belts, several factors need to be taken into account to ensure optimal performance. These factors include:

- Load capacity: The width of the belt should be able to handle the maximum load that the machinery will be subjected to during operation.

- Speed requirements: Higher speeds may require wider belts to prevent slippage and ensure efficient power transmission.

- Pulley size: The width of the belt should match the size of the pulleys it will be running on to prevent misalignment and premature wear.

- Application-specific requirements: Different industries and applications may have unique requirements that dictate the ideal belt width for optimal performance.

#### Calculating the Optimal Belt Width

To calculate the optimal width for industrial flat transmission belts, you can use the following formula:

\[ \text

<1000 \times C> \]

Where:

- Belt Width is the width of the belt in millimeters.

- P is the power transmitted in kilowatts.

- V is the belt speed in meters per second.

- C is the belt capacity factor.

##### Tips for Choosing the Right Belt Width

Based on the factors mentioned above, here are some tips to help you choose the right width for your industrial flat transmission belts:

1. Consider the maximum load and speed requirements of your machinery to determine the appropriate belt width.

2. Consult with belt manufacturers or suppliers to get expert advice on selecting the right width for your specific application.

3. Take into account any unique requirements or constraints that may affect the choice of belt width, such as space limitations or installation considerations.

### FAQs

#### Q: Can I use a wider belt than necessary for my application?

A: While using a wider belt may provide added durability and load capacity, it can also lead to increased friction and power loss. It is best to choose a belt width that matches the requirements of your specific application.

#### Q: How can I determine the optimal belt width for my machinery?

A: You can use the formula mentioned above to calculate the optimal belt width based on the power transmitted, belt speed, and capacity factor of your industrial flat transmission belts.

#### Q: What are some common belt width options available in the market?

A: Industrial flat transmission belts come in a variety of width options, ranging from a few millimeters to several inches, depending on the specific requirements of the application.

#### Q: How often should I replace industrial flat transmission belts?

A: It is recommended to replace industrial flat transmission belts at regular intervals to prevent unexpected failures and downtime. The frequency of replacement will depend on factors such as operating conditions and maintenance practices.

#### Q: What are some signs that indicate the need for belt replacement?

A: Signs such as excessive wear, cracking, or stretching of the belt indicate that it may be time for replacement to prevent potential damage to machinery and ensure continued operation.

# Conclusion

Choosing the right width for industrial flat transmission belts is a crucial decision that can impact the efficiency and performance of your machinery. By considering factors such as load capacity, speed requirements, and application-specific needs, you can select the optimal belt width to ensure smooth and reliable power transmission. Consult with belt manufacturers or suppliers for expert guidance and make an informed choice to optimize the performance of your industrial equipment.

Preceding Page:

Related News