Practical Knowledge about Rubber V Belts in Industrial Equipment and Components

Rubber V belts play a vital role in the industrial equipment and components sector, specifically in power transmission belts. These belts are known for their high flexibility, durability, and efficiency in transferring power between rotating shafts. In this article, we will explore some practical knowledge about rubber V belts, their applications, features, and maintenance.

1. Understanding the Application:

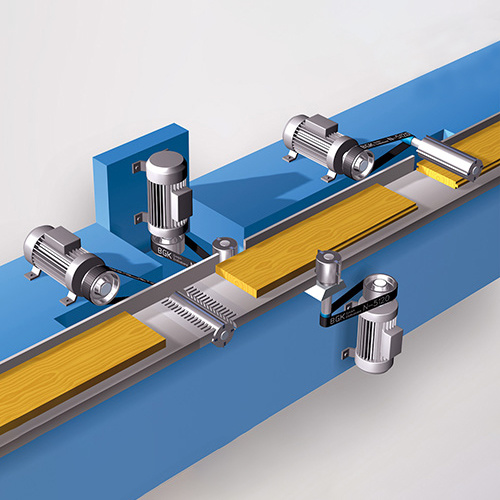

Rubber V belts are extensively used in various industries, including manufacturing, mining, agriculture, and automotive, to transfer power from engines or motors to different machine components. They are commonly found in conveyor systems, industrial machinery, generators, and many other applications that require efficient power transmission.

2. Key Features and Advantages:

Rubber V belts offer several features and advantages that make them a preferred choice in industrial settings:

- High flexibility and excellent grip: The V-shaped design ensures proper contact with the pulleys, enabling efficient power transmission.

- Resistance to environmental factors: Rubber V belts are resistant to oil, heat, and other environmental conditions, making them suitable for demanding applications.

- Reduced vibration and noise: The design and material properties of rubber V belts help dampen vibrations and minimize noise during operation.

- Wide range of sizes and configurations: Rubber V belts are available in various sizes and configurations to accommodate different power requirements and equipment designs.

3. Maintenance Tips:

To ensure optimal performance and longevity of rubber V belts, it is essential to follow proper maintenance practices:

- Regular inspection: Check for signs of wear, cracks, or damage on the belt surface. Replace any damaged belts promptly.

- Proper tensioning: Maintain the correct tension in the rubber V belts to prevent slippage and excessive wear. Follow the manufacturer's guidelines for tension adjustment.

- Keep pulleys clean: Clean the pulleys regularly to remove dirt, debris, and other contaminants that can affect belt performance.

- Avoid overloading: Ensure that the power transmission system does not exceed the belt's recommended load capacity to prevent premature failure.

In conclusion, rubber V belts are indispensable components in industrial equipment and power transmission belts. Understanding their application, features, and maintenance is crucial for ensuring smooth operations and efficient power transfer. By following proper maintenance practices, including regular inspection, correct tensioning, and pulley cleanliness, industries can maximize the reliability and lifespan of rubber V belts, contributing to overall productivity and cost-effectiveness.

1. Understanding the Application:

Rubber V belts are extensively used in various industries, including manufacturing, mining, agriculture, and automotive, to transfer power from engines or motors to different machine components. They are commonly found in conveyor systems, industrial machinery, generators, and many other applications that require efficient power transmission.

2. Key Features and Advantages:

Rubber V belts offer several features and advantages that make them a preferred choice in industrial settings:

- High flexibility and excellent grip: The V-shaped design ensures proper contact with the pulleys, enabling efficient power transmission.

- Resistance to environmental factors: Rubber V belts are resistant to oil, heat, and other environmental conditions, making them suitable for demanding applications.

- Reduced vibration and noise: The design and material properties of rubber V belts help dampen vibrations and minimize noise during operation.

- Wide range of sizes and configurations: Rubber V belts are available in various sizes and configurations to accommodate different power requirements and equipment designs.

3. Maintenance Tips:

To ensure optimal performance and longevity of rubber V belts, it is essential to follow proper maintenance practices:

- Regular inspection: Check for signs of wear, cracks, or damage on the belt surface. Replace any damaged belts promptly.

- Proper tensioning: Maintain the correct tension in the rubber V belts to prevent slippage and excessive wear. Follow the manufacturer's guidelines for tension adjustment.

- Keep pulleys clean: Clean the pulleys regularly to remove dirt, debris, and other contaminants that can affect belt performance.

- Avoid overloading: Ensure that the power transmission system does not exceed the belt's recommended load capacity to prevent premature failure.

In conclusion, rubber V belts are indispensable components in industrial equipment and power transmission belts. Understanding their application, features, and maintenance is crucial for ensuring smooth operations and efficient power transfer. By following proper maintenance practices, including regular inspection, correct tensioning, and pulley cleanliness, industries can maximize the reliability and lifespan of rubber V belts, contributing to overall productivity and cost-effectiveness.

Related News

TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD

0086(0595)83112333

0086(0595)83112333

© Copyright 2024. TIGER(FUJIAN) INDUSTRIAL BELT CO.,LTD.

Business License